Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Use our If-Then decision map to match materials, accuracy, and features to the right 5-axis bridge saw configuration. See neutral comparisons vs. other processes.

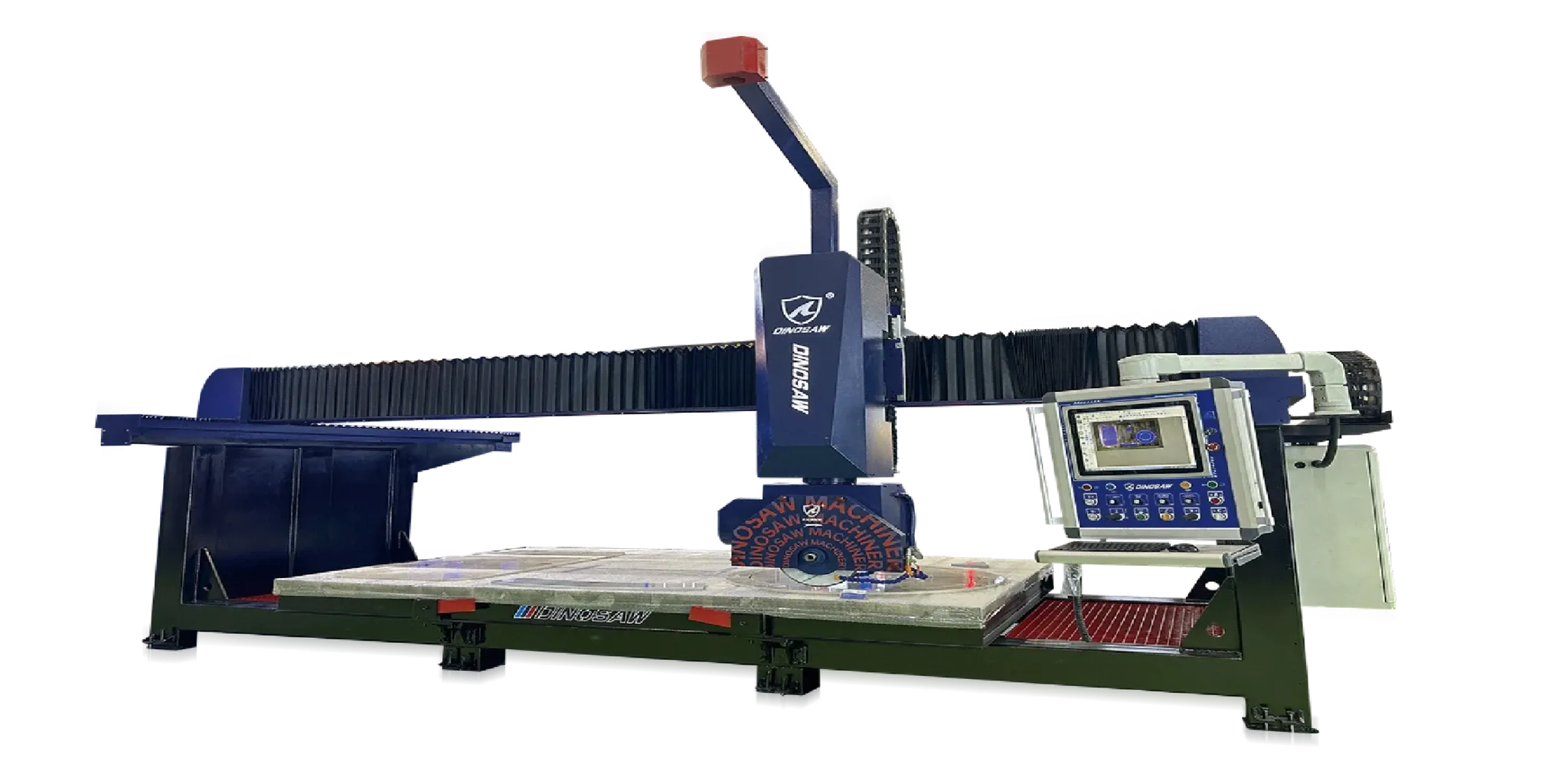

Choosing the right CNC 5 axis bridge saw is a critical capital investment. The goal is to avoid overspecifying features you won’t use or under-specifying a machine that can’t handle your future workload. This guide provides a clear decision map for procurement and engineering teams, mapping common use cases—like complex sink cutouts, curved countertops, and 3D elements—to the right machine envelope, blade diameter, control features, and material handling options.

We will walk through the key decision dimensions, provide If-Then recipes for common scenarios, offer neutral comparisons against other fabrication methods, and cover essential procurement topics to ensure you make a smart, future-proof investment.

Key Decision Dimensions

Before evaluating specific models, define your operational needs across these core dimensions. A detailed breakdown of machine components can be found in the Anatomy of a CNC Bridge Saw guide.

- Material Mix: What percentage of your work involves granite, marble, quartz, or ultra-compact surfaces like sintered stone?

- Complexity and Accuracy: Do your jobs require mitered edges, complex curves, and sink cutouts with tight tolerances?

- Automation Level: How important are features like camera nesting for yield optimization and direct DXF/DWG import for reducing programming time?

- Footprint and Installation: What are the physical constraints of your facility? Monoblock designs offer simpler installation compared to traditional bridge saws requiring separate concrete walls.

- Total Cost of Ownership: Beyond the initial price, consider factors like consumables, maintenance, and training. Our CNC Bridge Saw Price Guide offers more detail on this.

- Upgrade Path: Do your jobs require drilling and edge polishing (5+1 axis) or frequent repositioning of cut parts (5+2 axis)?

If-Then Selection Paths

Use these scenarios to map your needs to specific machine capabilities.

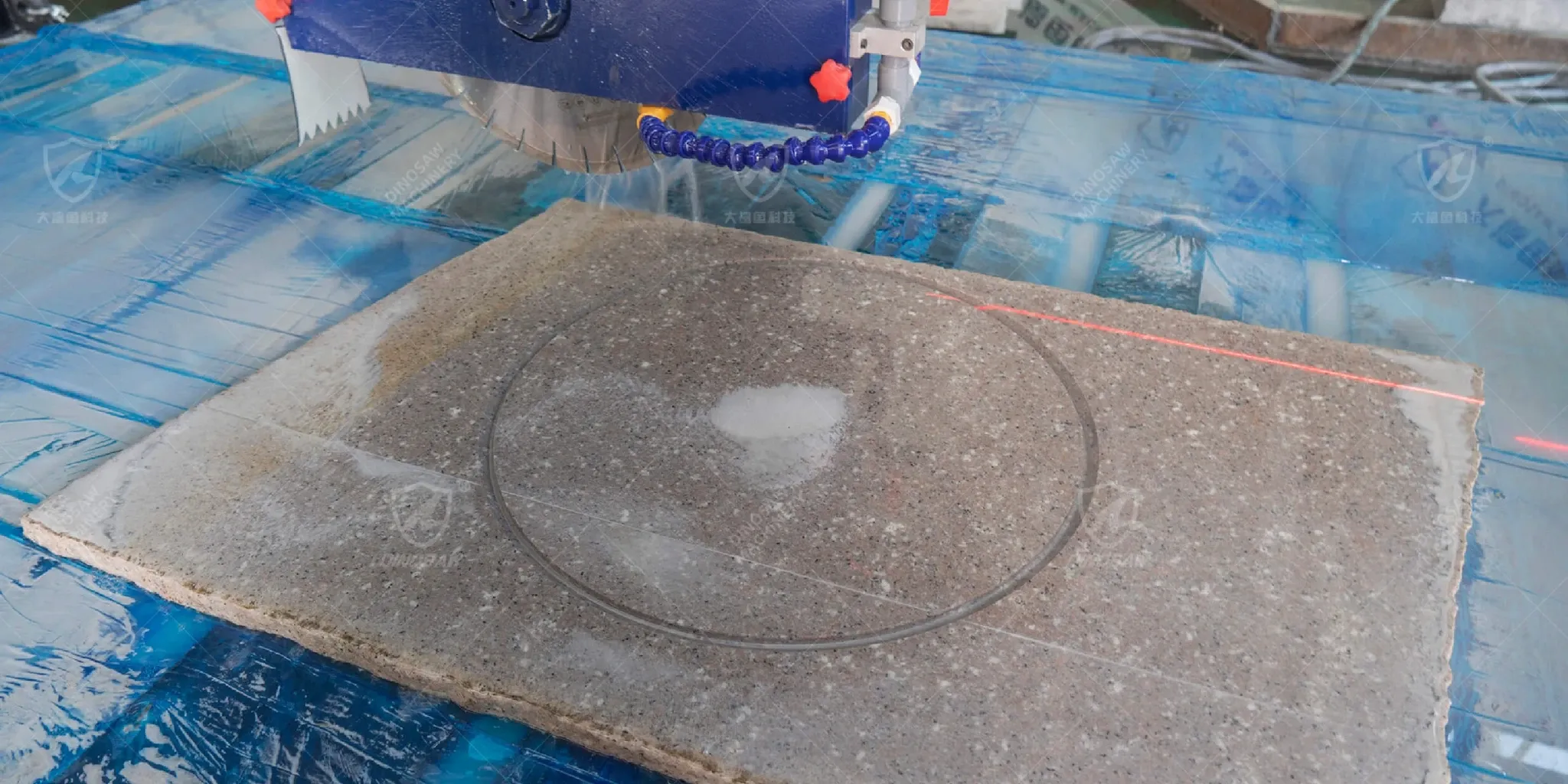

- IF you process high volumes of quartz undermount sinks, THEN prioritize camera nesting and vacuum handling. Risk Note: Without automated nesting, yield can drop significantly, and manual handling risks chipping.

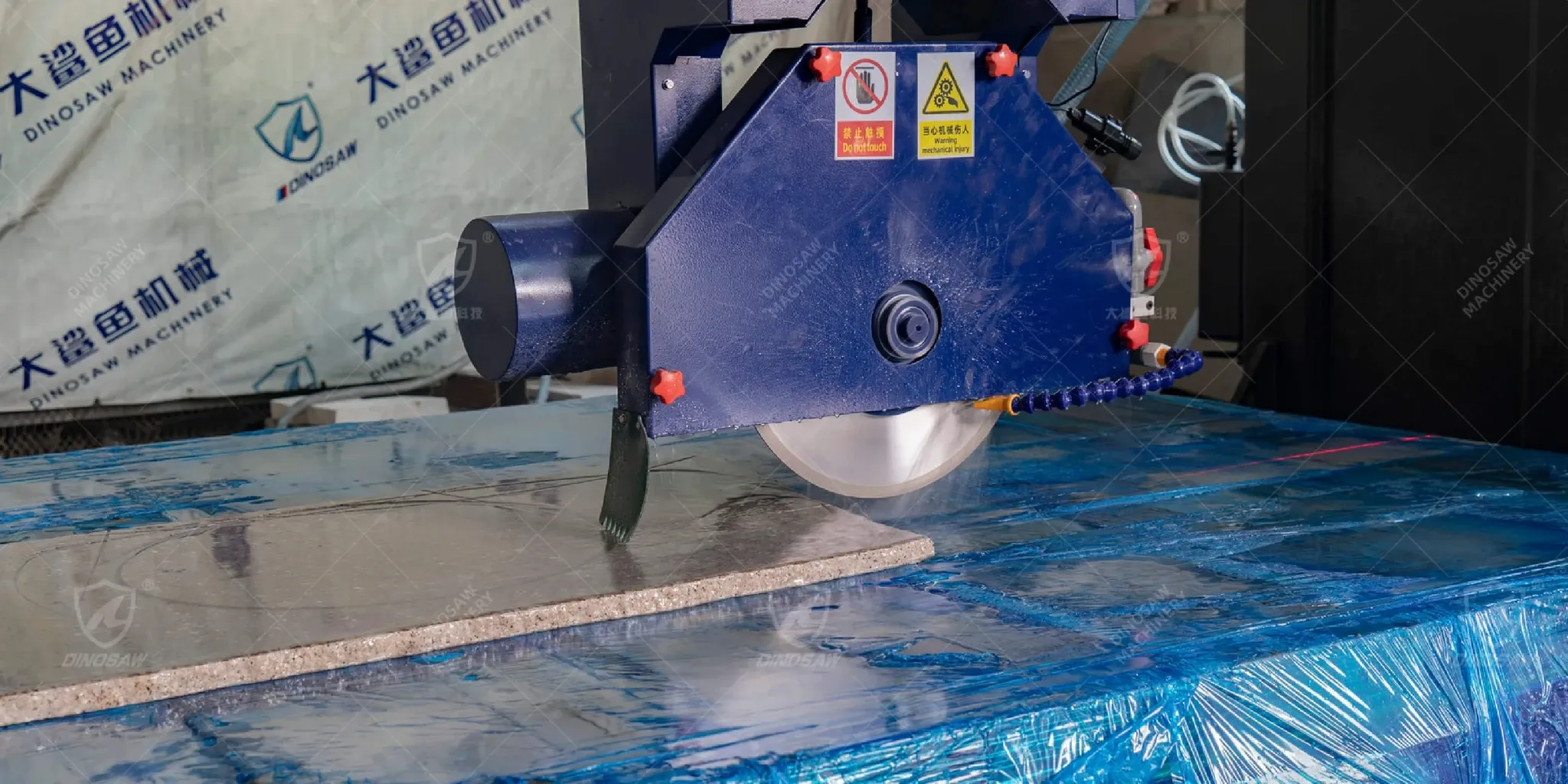

- IF your primary material is sintered stone or porcelain (≥12 mm), THEN ensure the machine offers precise coolant flow control and supports fine-grit blades. Risk Note: Improper cooling and blade selection are leading causes of micro-cracks and chipping in these brittle materials.

- IF you fabricate custom marble vanities with vein matching, THEN a high-resolution camera and intuitive nesting software are non-negotiable. Risk Note: Basic nesting systems cannot accurately align patterns across multiple components, leading to waste and aesthetic rejects.

- IF your projects include curved furniture or architectural elements, THEN opt for the larger Ø800 mm (31.5 in) blade capability for deeper, smoother 3D cuts. Risk Note: A standard blade may require multiple passes or create a stepped finish on deep curves, increasing finishing time.

- IF you operate in a shop with limited space, THEN a monoblock design is essential for its compact footprint and simplified installation. Risk Note: Non-monoblock saws often require dedicated foundations and more extensive site preparation.

- IF you export finished products to Europe, THEN verify the machine's certifications and compliance with standards like the EU Machinery Regulation 2023/1230. Risk Note: Non-compliance can lead to import restrictions and legal issues.

- IF your jobs frequently require drilling or edge polishing, THEN select the optional milling tool (5+1-axis configuration). Risk Note: Without it, these secondary operations will require moving the piece to another workstation, increasing handling time and risk of damage.

- IF your nesting requires repositioning parts mid-job or you need to avoid blade overcuts, THEN select the CAM-integrated vacuum suction (part of the 5+2-axis configuration). Risk Note: Manually moving heavy, freshly cut parts is inefficient and a significant safety hazard.

Neutral Comparison: 5-Axis Saw vs. Other Methods

| Method | Best For | Limitations |

|---|---|---|

| 5-Axis CNC Bridge Saw | Complex jobs: miter cuts, sink cutouts, curves, and batch production of countertops. | Higher initial investment; not ideal for extremely intricate inlay work (better suited for waterjet). |

| 3-Axis CNC Bridge Saw | Straight cuts and simple sink cutouts at a lower price point. | Requires multiple setups for miter cuts and cannot perform complex curved or 3D cutting. |

| Manual Stone Cutter | Low-volume shops focused on basic straight cuts. | Highly dependent on operator skill; slow, low precision, and unsuitable for complex shapes. |

| Waterjet Cutter | Extremely intricate designs, tight inside corners, and cutting materials a blade cannot handle. | Significantly higher operational costs (garnet, power, maintenance); slower on thick materials and less efficient for simple straight cuts. |

Essential Procurement Topics

Beyond the machine's technical specifications, consider these long-term operational factors. A comprehensive Granite Bridge Saw Buyer’s Guide can also provide additional context.

- Spare Parts & Consumables: Verify lead times for critical components like spindle bearings, vacuum pads, and common electronic parts.

- Training: What level of training is included? The claim of "5 minutes skilled operation" typically assumes a trained operator is learning a new interface, not a novice.

- Delivery & Installation: Confirm what is included—rigging, leveling, calibration, and initial test runs.

- Warranty & Service: Clarify warranty coverage for mechanical parts vs. electronics. What are the response times for on-site service?

- Certifications: Ensure the machine carries necessary certifications like CE marking for the European market. According to the European Commission, this is mandatory for market access. The new EU 2023/1230 regulation will be mandatory from January 2027, as noted by sources like TUV Rheinland.

Summary and Recommendation

For high-volume fabricators focused on kitchen and bath projects, a 5-Axis Bridge Saw for Sinks & Countertops offers a compelling blend of precision, speed, and versatility that manual, 3-axis, or even waterjet systems cannot match for this specific application. It excels at complex, repeatable tasks that define modern stone fabrication. While the initial investment is higher than a 3-axis machine, the dramatic reduction in setup time, material waste, and manual finishing provides a clear path to ROI for shops ready to scale.

Frequently Asked Questions

When should I choose the optional Ø800 mm blade capability?

Opt for the Ø800 mm (31.5 in) blade if you frequently work with very thick slabs (over 150 mm / 6 in) or fabricate complex 3D architectural elements and solid stone furniture. For standard countertop and sink production, the standard Ø600 mm (23.6 in) blade is sufficient.

Does DXF/DWG import significantly reduce programming time?

Yes, absolutely. Direct file import allows you to take a design straight from a CAD program to the machine, eliminating the need to manually program complex curves and cutouts on the HMI. This drastically reduces the risk of human error and cuts programming time from hours to minutes for complex jobs.

How do I evaluate the ROI of a camera nesting system?

To evaluate the ROI, calculate your current average slab waste percentage. A good camera nesting system can improve material yield by 15-30%, especially with expensive or patterned materials. Multiply that material saving by your annual material spend to quantify the direct financial benefit.

What warranty coverage should I expect for the spindle?

Spindles are high-wear components and often have a separate, shorter warranty period than the main machine frame (e.g., 6-12 months is common). Always clarify the specific warranty term for the spindle and what it covers (e.g., bearings, motor).