Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Decide head count and abrasive system to hit slabs/hour and finish KPIs. Quick checklists, decision map, and ROI levers included.

For decision-makers in the stone fabrication industry, the fundamental challenge is balancing throughput, quality, and cost. A well-sized continuous stone polishing line directly addresses this by increasing slab-per-hour output and improving yield, while simultaneously providing control over operational expenditure (OPEX). The key is to make a strategic choice based on your specific material mix and key performance indicators (KPIs) for finish quality.

What This Machine Is & Who This Guide Is For

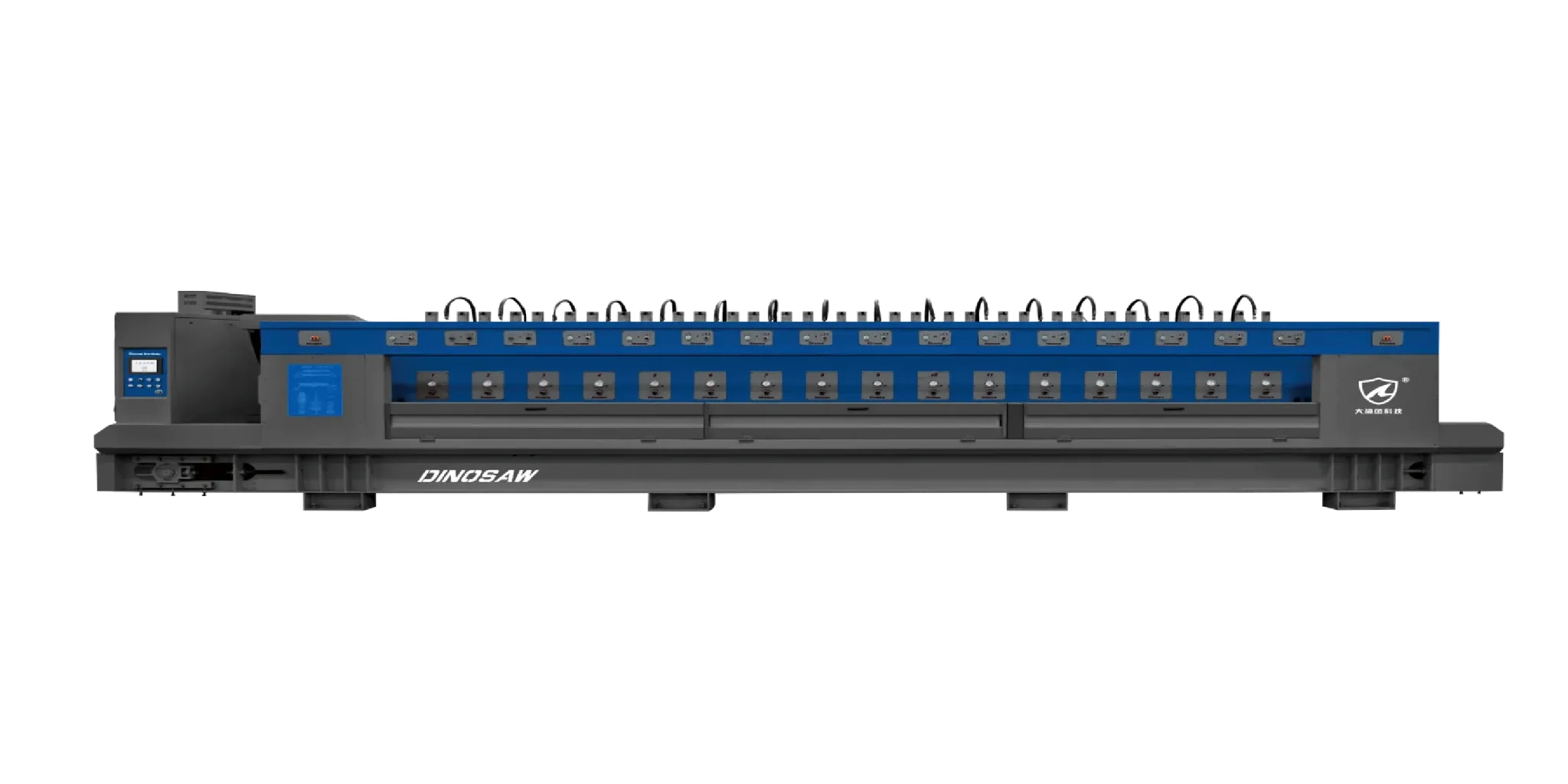

At its core, the automatic stone polishing machine for slab is an automated system that uses a sequence of 10-20 polishing heads to finish large stone slabs. It comprises a conveyor, a laterally moving cross-beam holding the heads, and precisely controlled abrasive, pressure, and water systems. G-series models use Fickert abrasives for hard stone like granite, while M-series models use Frankfurt abrasives for softer stone like marble.

This executive guide is for the joint decision-making team—including procurement, engineering, operations, and finance—who need a high-level overview of the technology's business impact and a clear roadmap for investment.

Quick-Start Decision Checklist

Use this checklist to frame your internal discussions before engaging with a vendor.

- Production Goal: What is your target \(m^{2}/hour\) for granite vs. marble? Use manufacturer-reported benchmarks (e.g., a 16-head line polishes marble at \(≈240 ~m^{2}/h\) and granite at \(≈290 ~m^{2}/h\)) as a starting point.

- Material Mix: What percentage of your business is granite vs. marble vs. engineered stone?

- Finish Quality KPI: What is the required gloss unit (GU) level and acceptable variance (ΔGU), as measured by standards like ISO 2813?

- Facility Readiness: Do you have adequate power, water supply/recycling, and floor space for the machine's footprint (e.g., a 20-head line can exceed 13 meters in length)?

- Automation Level: Are you seeking to add a slab turnover machine for a fully automated process? Industry 4.0 data interfaces can be provided on request (vendor-specific).

- Compliance: Is CE marking under the EU Machinery Regulation 2023/1230 a requirement for your market?

Summaries of In-Depth Guides

This executive summary is supported by four detailed guides for your functional teams.

Executive Keyword Overview

This guide to continuous slab polishing covers the stone slab polishing machine for granite/marble. A multi-head line is assessed on slabs/hour throughput, OPEX, CE Machinery Regulation and ISO 2813 compliance, reliance on PLC recipes, and the optional turnover machine.

- Automatic slab polishing Line Applications & Use Cases: Details how the technology solves common problems like low throughput and inconsistent gloss, with mini-case studies quantifying the ROI. See

- Automatic slab polishing Line Technical Principles: A guide for engineers on the mechanics of the conveyor, cross-beam, and spindle systems, including parameter ranges and failure modes.

- Automatic slab polishing Line Selection Factors: An If-Then decision tree to help procurement and engineering select the right head count and abrasive system based on material mix and production goals.

- Automatic slab polishing Line Operation & Maintenance: SOPs, troubleshooting flows, and safety checklists for operators and maintenance crews to maximize uptime and ensure safety.

Key ROI Levers

Investment in a continuous polishing line impacts four primary financial levers:

- Productivity (Throughput): Directly increases revenue potential by raising the number of finished slabs per hour.

- Operating Cost (OPEX): Optimizes use of consumables (abrasives), energy, and water, lowering the cost per square meter.

- Quality Yield: Reduces defect and rework rates, converting more raw material into sellable, high-margin product.

- Downtime: Minimizes time lost to material changeovers and manual handling, increasing overall asset utilization.

Glossary of Key Terms

- Fickert Abrasives: Rectangular abrasives used in G-series machines, ideal for grinding hard stone like granite.

- Frankfurt Abrasives: Wedge-shaped abrasives for M-series machines, designed for polishing softer stone like marble.

- Cross-Beam Swing: The lateral, oscillating movement of the beam that holds the polishing heads.

- Belt Speed: The speed at which the conveyor moves a slab through the machine.

- Gloss Units (GU): A standardized measure of specular gloss, indicating the reflectivity of a surface.

- OPEX: Operational Expenditure; the ongoing costs to run the machine.

- Turnover Machine: An optional, automated device that flips slabs over to polish the reverse side.

- Head Count: The total number of polishing spindles on the line (e.g., 12, 16, 20).

Frequently Asked Questions

What is the single biggest factor in choosing a machine?

Your material mix. If you process over 70% granite, you need a G-series machine with the power to grind it efficiently. If you primarily process marble, an M-series is more cost-effective. A balanced mix points toward a combined G/M model.

What is a realistic payback period?

This depends on your slab volume, margin improvement, and labor savings. A typical payback period can range from 18 to 36 months for high-volume fabricators, but a detailed ROI calculation should be done based on your specific financials.

Can one machine polish both granite and marble effectively?

Yes, combination G/M models are designed for this. They can accommodate both Fickert and Frankfurt abrasives and have the necessary power range. However, they represent a higher capital investment and require operators trained on both processes.

How does a continuous line compare to using robotic arms for polishing?

Robotic arms offer high flexibility for complex 3D shapes but generally have lower throughput for flat slabs. A continuous line is a specialized mass-production tool for slabs, while a robot is a versatile, lower-volume solution.

What KPIs should our management team track monthly?

Track these five core KPIs:

1) Throughput total ㎡/h;

2) Quality Yield defect/rework rate %;

3) Gloss Uniformity average GU variance;

4) OPEX (cost of consumables and energy per

5) Uptime (total productive hours vs. scheduled hours).

Who should lead the commissioning and training process?

This should be a joint effort. The vendor's technician should lead the technical commissioning and initial operator training. Your plant engineering or maintenance lead should shadow them to understand the machine's mechanics and electronics. A good training checklist includes: safety procedures, daily startup/shutdown, material changeover, PLC recipe management, and basic troubleshooting.

Next Steps

The implementation of a continuous polishing line follows a clear path from evaluation to full production.

- Pilot & Acceptance: Work with the manufacturer to test-polish samples of your specific stone. Define clear acceptance KPIs for throughput and finish quality before shipment.

- Standardize: After commissioning, create standardized recipes (PLC settings) for your top 5-10 most common materials.

- Scale & Replicate: Once the process is stable and ROI is proven, use the performance data to justify future capacity expansion or replicate the setup in other facilities.