Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Use If‑Then trees to pick head count and abrasive system based on your material mix and throughput goals. Covers OPEX, spares, training, warranty, and CE compliance.

Selecting the right continuous stone polishing line is a strategic decision that directly impacts operational expenditure (OPEX), throughput, and finish quality. The optimal configuration is not a one-size-fits-all solution; it’s a careful balance of head count and abrasive system tailored to your specific material mix and production goals. Starting with a clear understanding of your throughput targets and finish specifications is the most effective path to a profitable investment.

Get a head-count recommendation and cost model for your material mix.

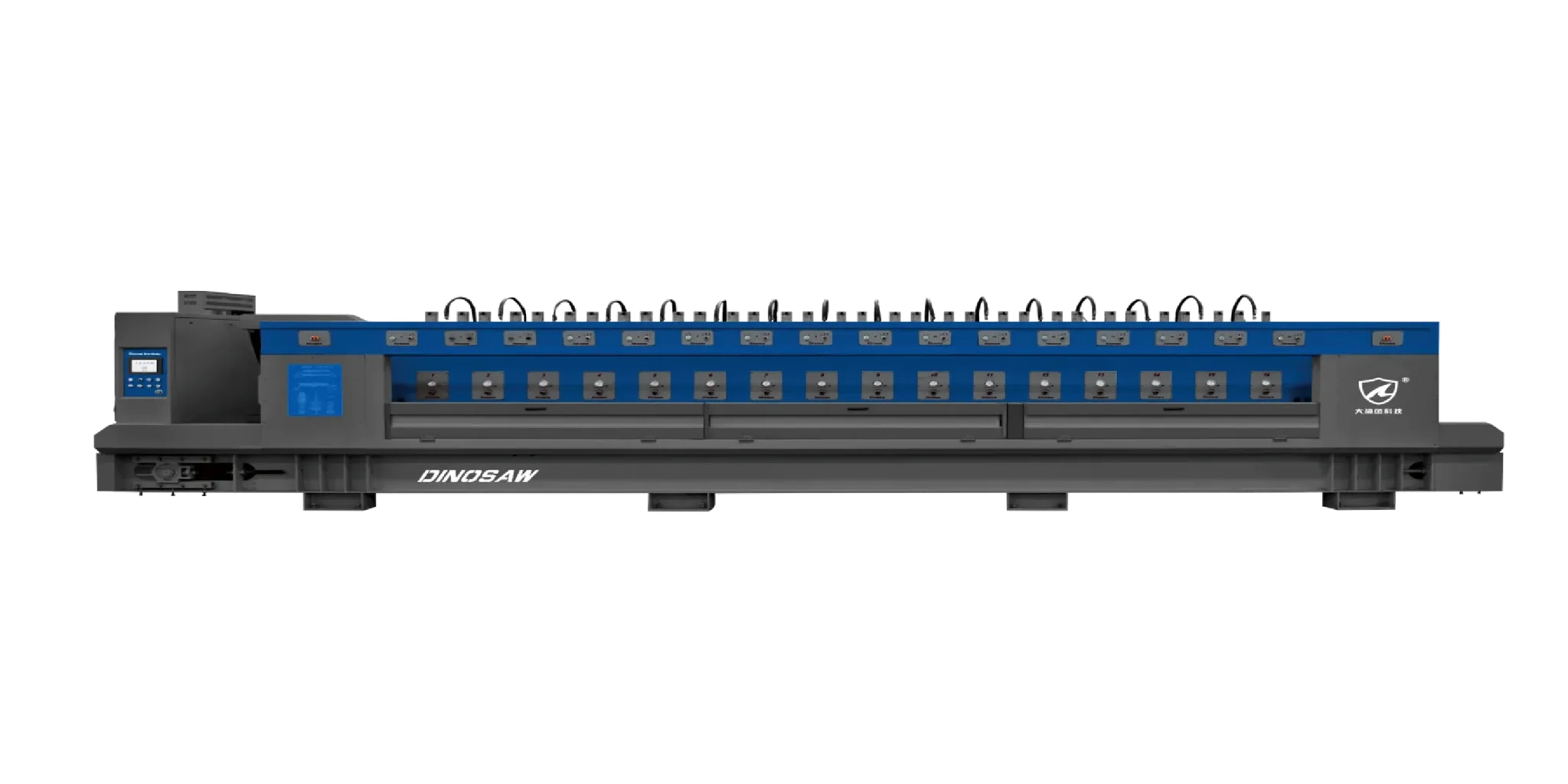

This guide provides a decision-making framework for procurement managers and engineers, breaking down the selection process into clear, actionable steps. We’ll use the TBMJ/DBMJ series as a reference, covering G-series models for granite (with Fickert/grinding discs) and M-series for marble (with Frankfurt abrasives), with configurations ranging from 10 to 20 heads. For base specifications, refer to the main automatic stone polishing machine for slab product page.

Key Decision Dimensions of Automatic Slab Polishing Line

Before evaluating specific models, define your requirements across these seven critical dimensions:

- Material Mix: What is the percentage split between hard stones (granite) and softer stones (marble, travertine)? This is the primary driver for selecting a G-series vs. an M-series line.

- Finish Specification: What is the target gloss level (measured in Gloss Units, GU) and required surface flatness? Achieving a mirror finish on dense granite requires more polishing stages (i.e., more heads) than a standard polish on marble.

- Throughput Target ㎡/h: What is your required output per shift or day? As a baseline, a 16-head line has DINOSAW-reported benchmarks of 240 ㎡/h for marble and 290㎡/h for granite. Your target will heavily influence the required head count.

- Slab Dimensions: What are the typical widths and thicknesses of your slabs? Ensure the machine's working width (e.g., 600–2100 mm) and thickness capacity (e.g., 15–50 mm) align with your inventory.

- Utility Costs & Availability: What are your local costs for water and electricity? This will impact the OPEX calculation. A line with higher spindle power (e.g., 15 kW/head) and water consumption (e.g., \(28 ~m^{3}/h\)) will have different operating costs than a smaller configuration.

- Automation Level: Do you require a fully automated line with loading/unloading and slab turnover machines, or will a semi-automated process suffice? Automation reduces labor but increases upfront capital investment. Industry 4.0 data interfaces (e.g., Profinet/OPC UA) are available on request depending on plant architecture and vendor offering.

If-Then Decision Tree for Slab Polishing Machine Configuration

Use the following scenarios to map your needs to a recommended machine configuration.

Scenario 1: High-Volume Granite Production

- If: Your production is >70% granite and the primary goal is maximizing throughput (aiming for 290㎡/h or more).

- Then: Select a G-series line with 16 to 20 heads and high-power spindles (11-15 kW). Use a full sequence of metalbond and resin-bond Fickert abrasives.

- Risk: Higher initial CAPEX and energy consumption. Requires a robust water supply and recycling system.

Scenario 2: Marble-Dominant Production

- If: Your mix is primarily marble >70% and the focus is on a flawless, high-gloss finish.

- Then: An M-series line with 12 to 18 heads using Frankfurt abrasives is ideal. Spindle power of 7.5-11 kW is sufficient.

- Risk: This configuration is less efficient for processing occasional granite batches, as it lacks the grinding power.

Scenario 3: Balanced Mix, Flexible Workshop

- If: You process a relatively even mix of granite and marble and need to switch between them frequently.

- Then: A 16 to 20-head G/M combination model (e.g., DBMJ-2000-16G/M) is the best choice. It supports both Fickert and Frankfurt abrasives. A slab turnover machine is highly recommended to minimize downtime.

- Risk: Requires investment in two full sets of abrasives and operator training for both material types.

Scenario 4: Budget-Conscious Entry or Lower Volume

- If: You are transitioning from manual polishing or have lower volume requirements but still need automation.

- Then: A 10 or 12-head line offers a significant productivity boost over manual methods at a lower capital cost. An M-series for marble or G-series for granite are viable starting points.

- Risk: Lower head count limits the maximum achievable gloss and throughput, especially on hard granite. May not be suitable for high-end granite finishing.

Scenario 5: Engineered Stone (Quartz) Processing

- If: Your focus is on engineered stone.

- Then: A G-series line (12-16 heads) with specialized resin-bond abrasives for quartz is recommended. Slower belt speeds and controlled head pressure are critical to avoid burning the resin binders.

- Risk: Requires a separate set of parameters and abrasives. Running at granite speeds will damage the material.

Scenario 6: Maximum Automation for Labor Savings

- If: The primary driver is reducing labor costs and maximizing unattended operation.

- Then: A fully integrated line (16+ heads) with automatic loading racks, a slab turnover machine, and optional sensor-based abrasive wear detection (photoelectric/torque signatures, availability varies by vendor) is the solution.

- Risk: Highest capital investment and requires skilled maintenance technicians. More complex troubleshooting.

Comparison with Traditional Slab Polish Processes

A DINOSAW continuous polishing line provides distinct advantages over traditional and existing stone finishing methods, impacting everything from labor to quality.

- vs. Manual Polishing Benches: While manual polishing offers flexibility for one-off custom jobs, it suffers from inconsistency and high labor costs. A DINOSAW line delivers superior automation and precision, ensuring every slab meets the same quality standard with minimal operator intervention, which is critical for scaling production.

- vs. Single-Head Bridge Polishers: Bridge polishers are a step up from manual work but are inherently inefficient for volume production due to their stop-and-go nature. Our continuous line provides a massive throughput advantage by processing slabs in a single, uninterrupted pass. The integrated PLC recipes ensure repeatable quality that is difficult to achieve with the manual adjustments often required by older bridge polishers.

- vs. Legacy Semi-Automatic Lines: Older semi-automatic lines may lack the sophisticated controls of a modern system. DINOSAW lines offer better automation with more stable PLC systems, precise pneumatic pressure control, and inverter-driven motors. This translates to better energy efficiency, more consistent finishes, and enhanced safety features that comply with current standards like CE. Our focus on comprehensive service and training also ensures a smoother adoption curve.

Procurement and Total Cost of Ownership Topics

Beyond the initial machine price, procurement teams should evaluate the following points to understand the total cost of ownership (TCO).

- Spares & Consumables: Clarify lead times and costs for critical spares (spindle motors, bearings, belts) and abrasives (Fickert, Frankfurt). A reliable supply chain is essential. Our Stone Grinder Machine Guide provides context on abrasive types.

- Maintenance Window: What is the recommended daily, weekly, and monthly maintenance schedule? Factor this downtime into your production planning.

- Training & Commissioning: Ensure the purchase includes comprehensive on-site training for both operators and maintenance staff. A proper commissioning process is vital to hitting performance targets.

- Warranty & Support: What are the warranty terms for mechanical and electrical components? Is remote diagnostic support available?

- Certification: For the European market, confirm the machine is CE certified and comes with a Declaration of Conformity under the EU Machinery Regulation 2023/1230.

- Shipping & Logistics: These machines are typically shipped in a flat rack container. As noted in the DBMJ-2100-10G quotation, freight costs for special equipment fluctuate. For a destination like Lisbon, the shipping rate is subject to change based on the market price at the time of shipment. Build this contingency into your budget.

Frequently Asked Questions

How many heads do I really need for granite vs. marble?

For a high-gloss finish, marble typically requires more processing stages. A 16 to 20-head line is recommended for high-volume marble work. For granite, where less material needs to be removed to achieve a smooth surface, a 12 to 16-head line is often the most cost-effective choice.

When is a slab turnover machine worth the investment?

A turnover machine provides a positive ROI if you polish both sides of more than 40% of your slabs. The time saved by automating the flipping process and reducing manual labor and risk of damage quickly outweighs its cost in high-throughput environments.

Can I upgrade and add more heads later?

No, the machine frame, conveyor, and cross-beam are engineered for a specific number of heads. It is not feasible to add more heads to a line after it has been manufactured. It is crucial to select the correct head count for your future growth during the initial purchase.

What is the difference between a TBMJ and DBMJ model?

The model numbers often refer to different series or specific configurations from the manufacturer, such as machine width or intended material. For example, the DBMJ-2000-12G/M indicates a dual-purpose Granite/Marble machine with a 2000mm working width and 12 heads. Always refer to the specific model's spec sheet to confirm its capabilities.

Which is better for granite: a 16-head or 20-head line?

For most high-volume granite applications, a 16-head line offers an excellent balance of throughput and finish quality. A 20-head line is justified when the goal is to achieve the absolute highest gloss levels at maximum speed or when processing exceptionally dense and difficult-to-polish granites, as the extra heads allow for a more gradual and refined polishing sequence.

What if my slabs are mostly 2100 mm wide?

If your inventory is consistently at the maximum width, ensure you select a model specifically rated for that dimension (e.g., DBMJ-2100 series). This ensures the cross-beam swing and water distribution are optimized for full coverage, preventing unfinished edges or inconsistent gloss at the borders of the slab.

Can I run a continuous polishing line alongside existing bridge polishers?

Yes, this is a common workflow. The continuous line can handle all high-volume, standard-sized slabs, maximizing overall plant throughput. This frees up your bridge polishers for smaller, custom jobs, cut-to-size pieces, or rework, creating a more efficient and flexible factory floor.