Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Precision sink/countertop cutting for granite, quartz, ceramic, and marble. Achieve fast, clean results with 5-axis curves, miter seams, camera nesting, and DXF import.

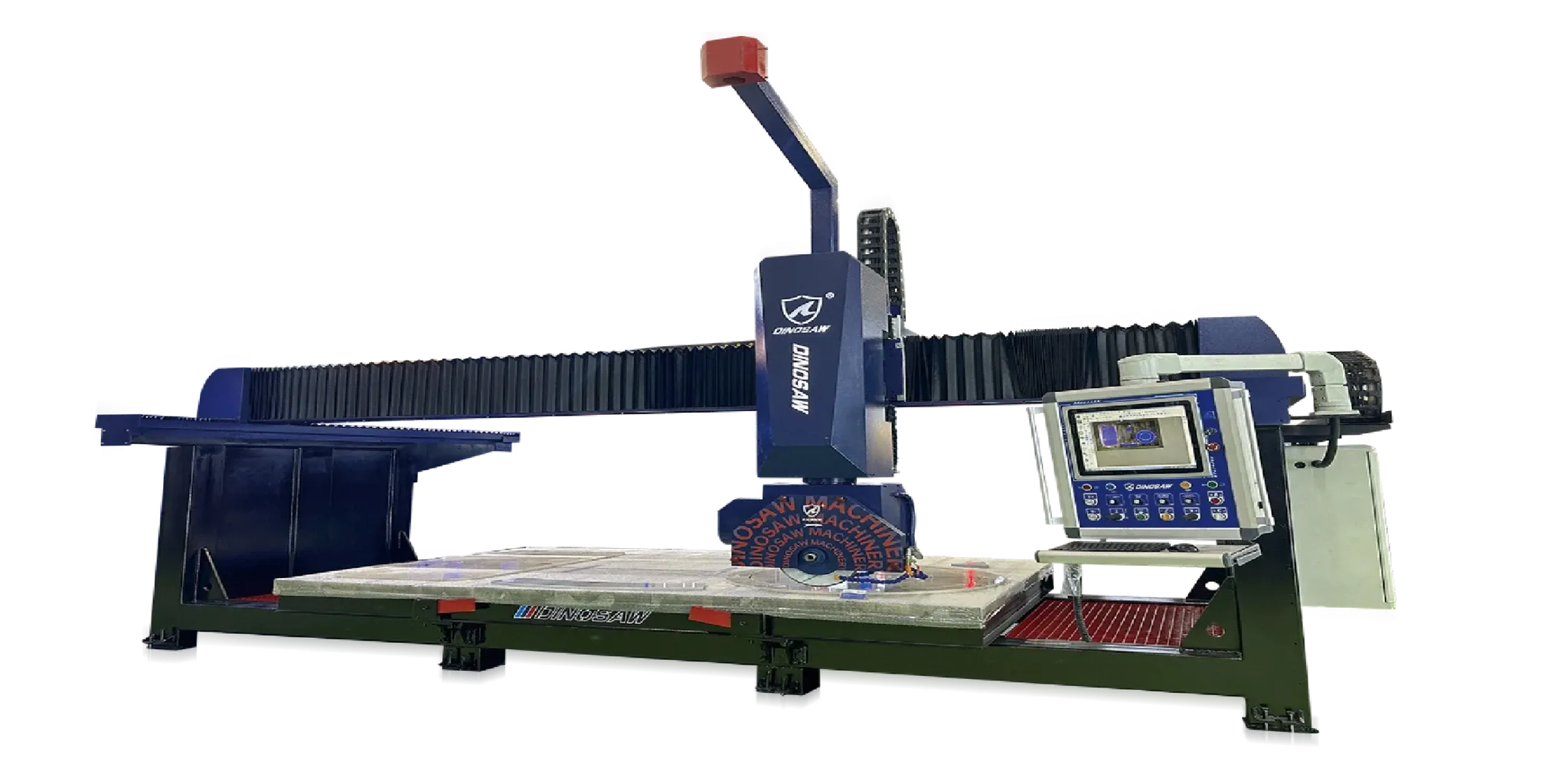

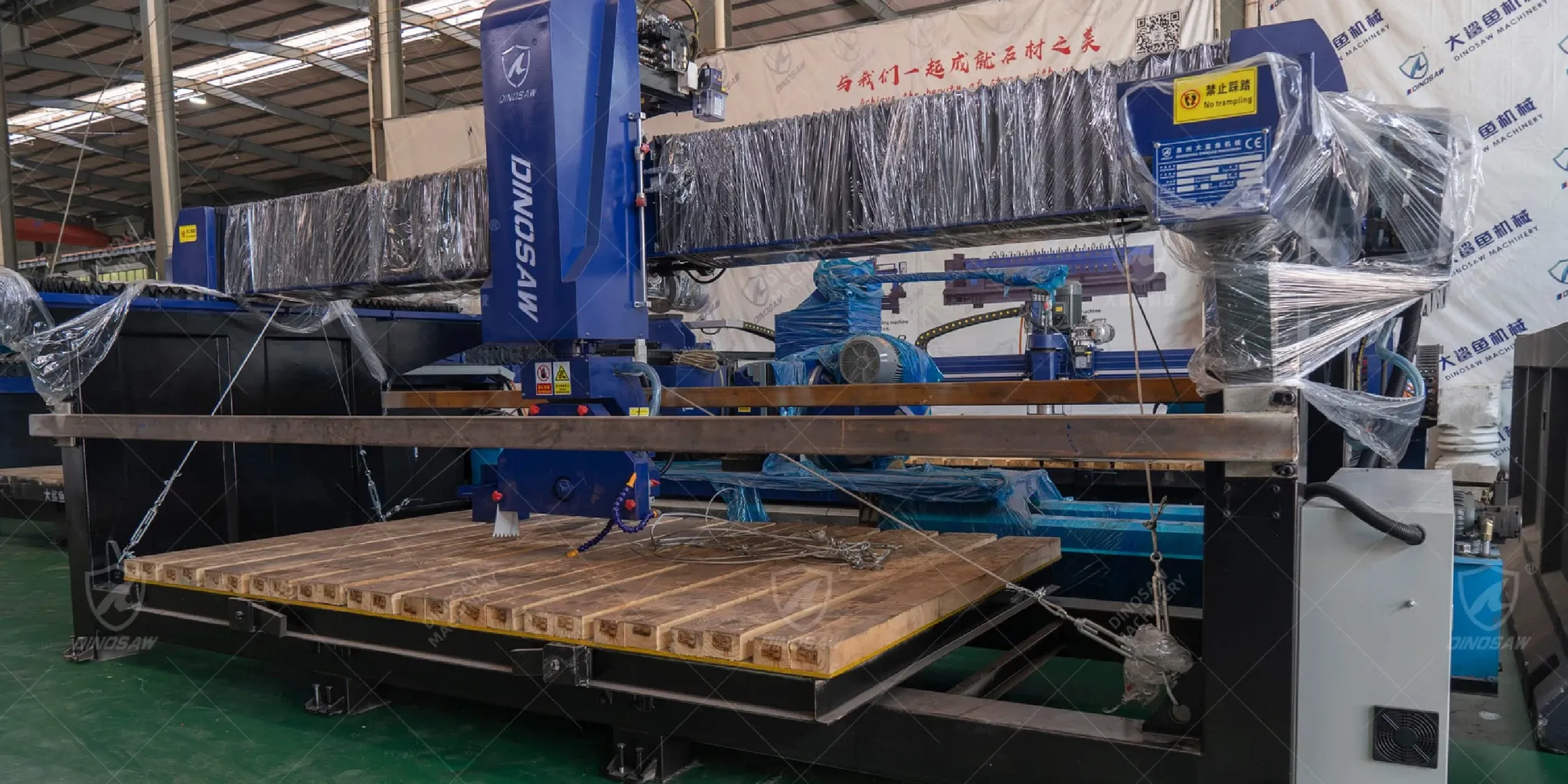

For kitchen and bath fabricators, delivering flawless sink cutouts and complex curved edges with repeatable precision is non-negotiable. The challenge lies in balancing speed and accuracy while minimizing material waste and manual finishing time. The DINOSAW WZQJ-5N 5-axis CNC bridge saw is engineered to solve this, transforming how shops process everything from granite sink fabrication to intricate marble vanity projects.

Talk to a material specialist about optimizing your sink and countertop workflow.

This application guide is for procurement managers and dealers focused on results. We will cover the materials, processing capabilities, and common problems this machine solves, with practical examples to show how it fits into a modern fabrication line. The WZQJ-5N is a 5-axis bridge saw designed for processing granite, marble, quartz, ceramic, and sintered stone for sinks, countertops, and curved elements, delivering a manufacturer-reported precision of ±0.05 mm.

Materials and Processing Compatibility

The machine’s versatility allows fabricators to confidently take on projects across a wide spectrum of materials. Its robust design and powerful spindle are suitable for both natural and engineered stone, ensuring high performance whether you're working on a standard quartz countertop or a custom porcelain piece.

- Compatible Materials: Granite, Marble, Quartz, Ceramic/Porcelain, Terrazzo, and Sintered Stone.

- Blade Capacity: Accommodates blades up to 600 mm (23.6 in) standard, with an optional upgrade to 800 mm (31.5 in) for deeper cuts and complex 3D work.

- Typical Processing Modes: Straight cutting, angled and miter cutting, arc and curved cutting, 3D shaping, drilling, and edge profiling/polishing.

- Camera System: Standard top-mounted HD camera for photo-based slab nesting and laser positioning. It automatically measures slab thickness and tool dimensions to optimize layout and increase material yield .

Processing Boundaries: What It Can and Cannot Do

Understanding the machine's operational limits is key to successful implementation.

- Can Do: Execute complex undermount sink cutouts, create precise arc edges for tables, produce perfect mitered seams for waterfall countertops, and run batch repeats for standardized products.

- Cannot Do: Process materials beyond the machine’s verified range for your material and thickness (consult the technical team before attempting), operate with blades outside the safe RPM range, or perform dry cutting, which is unsafe and violates regulations. According to OSHA's silica standard (29 CFR 1926.1153), wet cutting is mandatory to control respirable crystalline silica exposure.

Mini Cases: Real-World Applications

1. Quartz Sinks Batch Line

A fabricator automated their quartz sink production by creating a program for their most popular undermount model. Using camera nesting and vacuum handling, they now produce consistent, chip-free cutouts in batches, reducing per-unit cycle time by 40%. Parameters are saved as a recipe for "5 minutes skilled operation." (manufacturer-reported).

2. Marble Vein-Matched Vanities

For a high-end hotel project, a shop used the vision system to capture vein patterns on large marble slabs. The software nested the vanity top and integrated sink pieces to ensure a seamless flow of veining across the entire assembly, creating a premium, monolithic look that commanded a higher price.

3. Granite Countertop Miter Program

A dealer offering kitchen packages developed a standardized 45° miter cut program for granite countertops. The 5-axis head performs the angled cut and a slight back-cut for an epoxy channel in one pass, creating strong, nearly invisible seams. Initial parameters depend on slab hardness, blade spec, and cooling; validate with test cuts and record the final recipe.

From Common Fabrication Problems to Automated Solutions

Manual and semi-automated processes often introduce costly errors. The WZQJ-5N directly addresses these pain points with integrated technology.

Common Pain Points

- Breakage and chipping around sink cutouts.

- Vein mismatching on marble countertops.

- Slow, labor-intensive manual finishing.

- High slab waste from inefficient nesting.

Integrated Solutions

- 5-axis interpolation for smooth corners.

- Camera nesting to align patterns and maximize yield.

- Automated tool compensation for precision edges.

- Direct DXF/DWG file import for design fidelity.

- Optional milling tool (5+1-axis configuration) for drilling and edge polishing.

- Optional vacuum suction with CAM integration (5+2-axis configuration) for safer part repositioning and avoiding over-cuts.

Brief Processing Workflow

A simplified checklist for a typical job includes:

- Material Scan & Nesting: Use the camera system to capture the slab and nest DXF/DWG parts to optimize yield.

- Tool Selection: Choose the appropriate blade and tool path for the material and cut type.

- Set Parameters: Define initial parameters based on material guidelines, blade supplier charts, and past shop recipes; validate with a short test cut on scrap.

- Trial & Production: Run a trial kerf to verify settings, then proceed with the full production run.

- Capture Recipe: Save successful settings as a recipe for future repeat jobs.

Advantages Over Other Methods

When considering an investment, it's helpful to compare the 5-Axis Bridge Saw for Sinks & Countertops against other fabrication methods. For more details on system components, see our guide on the Anatomy of a CNC Bridge Saw.

- vs. Manual Saws: Delivers superior speed and repeatable precision, eliminating human error in complex cuts.

- vs. 3-Axis CNCs: Requires fewer setups for curved edges and mitered corners, as the 5-axis head can tilt and rotate in a single program.

- vs. Pure Waterjet: Offers lower operating costs for stone due to fewer consumables and excels at creating clean, sharp mitered edges that waterjets can struggle with.

Risks and Prerequisites

To maximize performance and safety, proper setup and operation are critical. A detailed plan for How to Maintain a Bridge Saw is crucial for long-term reliability.

- Operational: Consistent cooling quality, routine blade wear inspection, and secure slab clamping via the vacuum system are essential to prevent defects.

- Training: Operators require training on the DXF/DWG import process, camera nesting software, and setting material-specific parameters.

- Regulatory: Shops must adhere to local dust and water regulations. According to NIOSH safe work practices, engineering controls like wet cutting are a primary method for silica dust suppression.

Summary

The DINOSAW WZQJ-5N 5-axis bridge saw is a specialized tool for fabricators aiming to increase efficiency and capability in sink and countertop production. By automating complex cuts, minimizing waste through smart software, and handling a wide range of popular materials, it allows shops to take on higher-margin projects with greater confidence and repeatability. To understand how this fits into your budget, review our CNC Bridge Saw Price Guide.

Frequently Asked Questions

How do you cut undermount sink openings in quartz without chipping?

To prevent chipping, use a high-quality blade designed for quartz, ensure consistent water flow for cooling, and use a multi-pass cutting strategy with a slower feed rate on the final pass. The 5-axis head allows for a smooth entry and exit path, further reducing stress at the corners.

Can this machine align marble veining across a sink and counter?

Yes. The integrated camera system captures a high-resolution image of the entire slab. In the software, you can place the digital templates (DXF/DWG files) for the sink and countertop pieces precisely along the veins to create a continuous, matched pattern.

Should I choose a 600 mm or 800 mm blade for 3D features?

For most countertop and sink applications, the standard 600 mm blade is sufficient. The optional 800 mm blade is recommended for fabricators who regularly produce deep 3D-carved elements, thick architectural pieces, or need to process exceptionally thick blocks.

How does camera nesting improve yield for ceramic and porcelain?

Ceramic and porcelain slabs are expensive and brittle. The camera nesting software automatically arranges all parts to fit within the usable area of the slab, minimizing waste. It helps avoid any existing defects or micro-fractures, which is critical for preventing breakage during cutting.

How do I miter a 45° countertop seam for a waterfall edge?

The 5-axis head tilts to a 45° angle to perform the cut. For best results, the machine can be programmed to make the primary miter cut and then a second, slightly offset cut to create a channel for epoxy. This ensures a strong, tight, and almost invisible joint after assembly.

What starter parameters should be used for granite sink cutouts?

Starter parameters for granite are material-dependent, but a typical starting point should be based on blade manufacturer charts and refined with test cuts. It's crucial to perform a test cut on a scrap piece to fine-tune the feed rate and RPM based on the specific granite's hardness and composition, as confirmed by ASTM test methods for dimension stone.